The short answer is yes – But!

Bit of the History

In the 1970s, microbore pipes emerged as a revolutionary plumbing solution for central heating systems. These pipes, typically made of copper and measuring between 8mm and 10mm in diameter, offered flexibility and ease of installation by hand. Their design aimed to minimize the need for joints and soldering, thereby reducing the risk of additional leakage.

Installation of microbore pipes commonly involved connecting them to a manifold or directly to larger pipes with diameters of 15mm or 22mm. Manifolds, typically linked directly to boilers using 22mm pipes, played a crucial role in the system.

In more contemporary applications, modern microbore pipes for central heating are predominantly made from plastic, favored particularly by developers in new construction projects. While plastic microbore pipes are less prone to rust and sludge buildup, the radiators attached to them may still experience corrosion. Moreover, due to the narrower diameter of the pipe, blockages can still occur.

Is microbore pipe better than pipes with larger diameters?

Microbore piping is frequently chosen for its space-saving attributes, streamlined installation process, and effective reduction of heat loss within the pipework. Additionally, it offers a more budget-friendly option compared to alternative plumbing solutions.

What is the biggest disadvantage of the microbore?

Yes, You are Right! Blockages

Blockages are indeed a common issue with microbore systems. Due to their narrow internal diameter, even small corroded flakes from the radiator’s walls can lead to blockages. This problem is heightened in plastic pipework, as the installation of inserts further reduces the internal diameter, making blockages more likely.

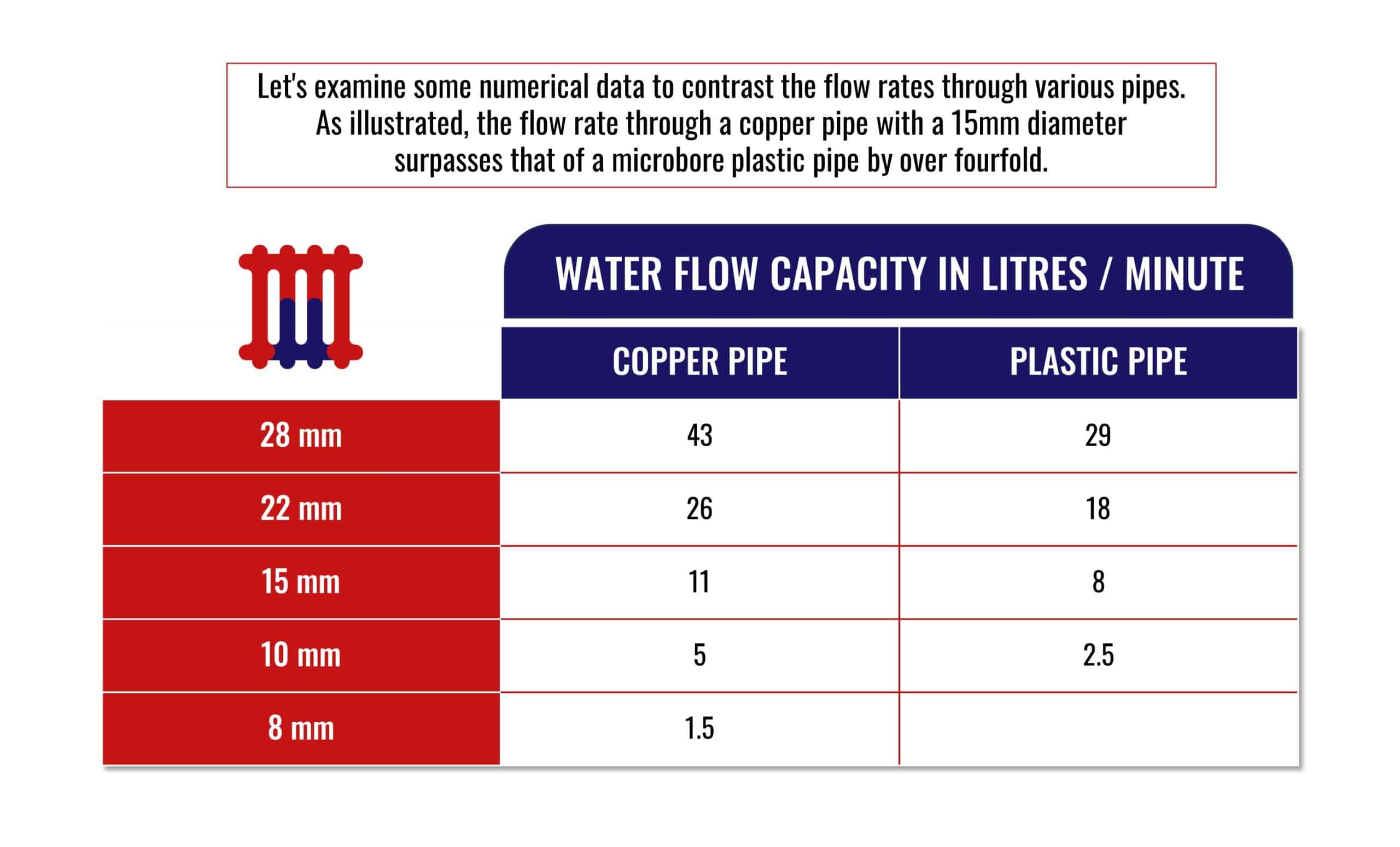

Let’s examine some data to contrast the flow rates through various pipes. As illustrated, the flow rate through a copper pipe with a 15mm diameter surpasses that of a microbore plastic pipe by over fourfold.

The Leading Cause of Heating System Failures

Poor water quality emerges as the primary factor contributing to heating system breakdowns. Drawing a parallel with your car, your heating system requires regular servicing for optimal functionality. While many individuals adhere to an annual car servicing routine, the same diligence is often overlooked for their heating systems.

It’s crucial to inspect water quality and inhibitor levels in your heating system annually. Employing a powerflush, a cleaning process, is essential for maintaining your system’s health. Experts recommend undergoing this comprehensive cleaning every 5-10 years, particularly if your system features microbore pipework.

Consider the repercussions of neglecting to change oil and service your car regularly. Similarly, overlooking your heating system’s maintenance could lead to significant issues, potentially necessitating a replacement.

We’ve noticed that some of our radiators aren’t functioning properly.

Typically, this is due to circulation issues within the heating system, often caused by either full or partial blockages in the pipework or within the radiator itself. When you encounter a malfunctioning heating system characterized by cold radiators and blocked pipes, you’re faced with two options:

Option one involves replacing the radiators and pipes throughout your home. This process typically entails lifting carpets, removing floorboards or tiles, and even plasterboard. It’s a costly solution, often amounting to several thousand pounds, and can be quite messy and expensive.

Option two entails attempting a Powerflush of the system. While this approach often resolves the issue and extends the longevity of your heating system, it’s not guaranteed to work in every case. The efficacy of a Powerflush is generally high, but in a small percentage of instances, particularly due to the narrow diameter of microbore pipes, it may not fully address the problem.

Yes! Microbore pipe can be Powerflushed.

However, it’s essential to recognize that due to the reduced flow rates, the efficacy of the flush may not match that of a standard larger bore system. Although heating systems with microbore piping can be power flushed, it’s crucial to consider some additional factors due to the smaller pipe diameter.

Powerflushing a system with microbore pipes may require more time and careful attention to ensure that cleaning agents effectively dislodge any sludge or debris without causing harm to the pipes. Overall, power flushing a microbore system is a more intricate process than a standard power flush and should only be carried out by experienced engineers using specialized equipment and chemicals. Additionally, the dosage of chemicals needs to be adjusted accordingly compared to systems without microbore pipes.

Are you on the verge of tossing your money out the window?

Despite the potential challenges, opting for a power flush in a microbore system still offers a more thorough cleaning than any alternative. The only superior option would entail replacing your heating system.