Can the Microbore pipe be Powerflushed?

Yes! Microbore pipe can be Powerflushed.

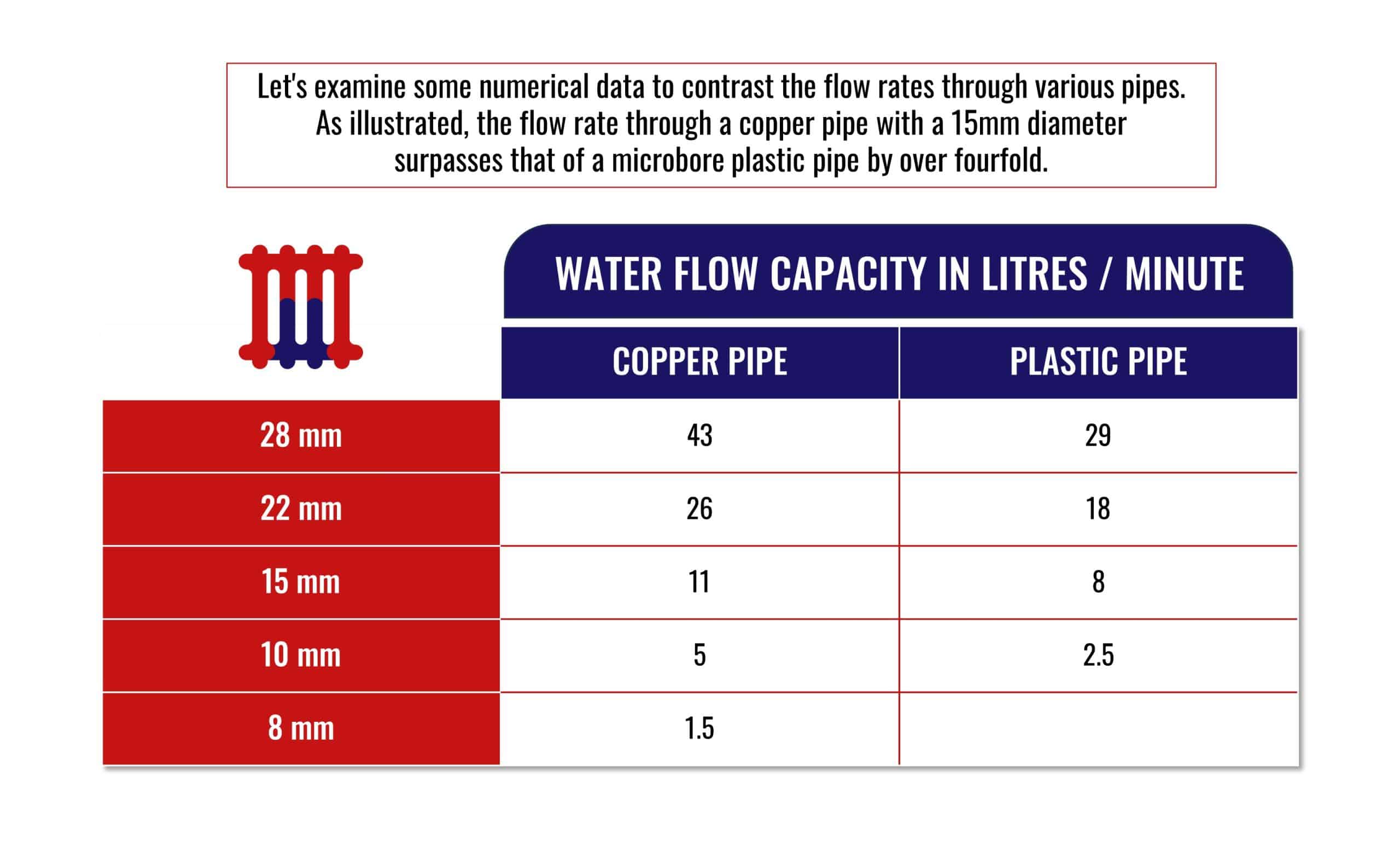

However, it’s essential to recognize that due to the reduced flow rates, the efficacy of the flush may not match that of a standard larger bore system. Although heating systems with microbore piping can be power flushed, it’s crucial to consider some additional factors due to the smaller pipe diameter.

Powerflushing a system with microbore pipes may require more time and careful attention to ensure that cleaning agents effectively dislodge any sludge or debris without causing harm to the pipes. Overall, power flushing a microbore system is a more intricate process than a standard power flush and should only be carried out by experienced engineers using specialized equipment and chemicals. Additionally, the dosage of chemicals needs to be adjusted accordingly compared to systems without microbore pipes.

What is Powerflush?

Powerflushing is a standard method for cleaning central heating by removing sludge, rust, and other dirt that builds up over time. It involves using high water flow to force water and chemicals through the pipes to remove any blockages and enhance the system’s functionality. There is usually confusion as to whether microbore powerflush is ideal for microbore pipes or not. Microborer pipes have diameters less than those of conventional pipes. They are widely used in heating systems because of their ease of installation and concealability behind walls. Nonetheless, due to their small size, they are also more prone to problems such as blockages.

Bit of the History

In the 1970s, microbore pipes emerged as a revolutionary plumbing solution for central heating systems. These pipes, typically made of copper and measuring between 8mm and 10mm in diameter, offered flexibility and ease of installation by hand. Their design aimed to minimize the need for joints and soldering, thereby reducing the risk of additional leakage.

Understanding Microbore Pipes

Microbore pipes are significantly smaller in diameter than most central heating pipes, which are about 15mm or 22mm in diameter, while microbore pipes are as small as 8mm or 10mm. They are commonly used for heating systems in the United Kingdom. Because they are small, they are suitable for installation in areas that have limited space, for instance, in apartments or homes where the piping should not be seen. Microbore systems are typically pipe systems having a common connection point to the radiators by way of a manifold that feeds the water across the radiators.

There are a number of benefits associated with microbore pipework since the pipework is compact in size. They are more compact and need less water to fill, so it is easier for the system to start heating up; they are easier and cheaper to fit than old system. Nonetheless, the downside is that most are likely to pose some blockages. Years of dust, rust, and accumulated debris accumulate within these small pipes and decrease efficiency, have cold rims in radiators, and cause blockage. This is why maintenance is essential for the microbore system, especially since it is installed in homes.

The Leading Cause of Heating System Failures

Poor water quality emerges as the primary factor contributing to heating system breakdowns. Drawing a parallel with your car, your heating system requires regular servicing for optimal functionality. While many individuals adhere to an annual car servicing routine, the same diligence is often overlooked for their heating systems.

It’s crucial to inspect water quality and inhibitor levels in your heating system annually. Performing a powerflush is essential for maintaining your system’s health. Experts recommend undergoing this cleaning every 5-10 years, especially if your system is made of microbore pipework.

We’ve noticed that some of our radiators aren’t functioning properly.

Typically, this is due to circulation issues within the heating system, often caused by either full or partial blockages in the pipework or within the radiator itself. You have two options:

Option one involves replacing the radiators and pipes throughout your home. This process typically entails lifting carpets, removing floorboards or tiles, and even plasterboard. It’s a costly solution, with a budget of several thousand pounds, and can be quite messy and expensive.

Option two is the Powerflush of the system. While this approach often resolves the issue and extends the longevity of your heating system, it’s not guaranteed to work in every case. The efficacy of a Powerflush is generally high, but in a small percentage of cases, particularly due to the small diameter of microbore pipes, it may not be fully successful.

What is Microbore Standard Power flush?

Powerflushing is a procedure that requires the use of a flushing machine to force water and chemical flush to circulate at a high flow rate in a central heating system. The idea is to ensure that the pipes or radiators are clean of any dirty sludge/ rust or debris that may have accumulated in the course of use. Power flushing assists in increasing and enhancing a heating system, minimizes energy expenses, and enhances the working life of the boiler and radiators.

Usually, the procedure involves connecting a power flushing machine to the heating system through the pump or a radiator. The machine then pumps water and a special cleaning chemical through the system at high speed. This aids in flushing out any sediment and dust that may have settled on the inner parts of pipes and radiators. The dirty water is then deposited out of the system and washed with clean water. Lastly, a corrosion inhibitor is used in the system to minimize the formation of future deposits. Powerflushing is widely regarded as a non-hazardous process for cleaning central heating systems, but it cannot be used on all systems and pipes. This is when the question of whether it is safe for microbore pipes arises.

Challenges of Powerflushing Microbore Pipes

Risk of Blockages:

Microbore pipes are smaller than regular pipes and, hence, tend to be blocked by sludge and debris. If debris accumulates within the pipes, a high-pressure power flushing machine may not effectively remove it, leaving a thoroughly blocked pipe. This can result in a situation where the water cannot flow in the right manner within the system; hence, the effectiveness of the system is compromised.

Difficulty in Access:

Another interesting point is that microbore systems have a low flow rate and if you add some blockages to it, you have just decreased the flow even further. If there is no flow even the power flushing machine can’t get chemicals in the areas where needed. Some of the areas in your piping system may not receive fresh water and chemicals evenly through the power flushing machine.

Manifold Issues:

Most common microbore systems use a manifold to distribute water to the radiators. However, these heating manifolds can become filled with sludge, and power flushing does not always produce enough flow to clean them. In some cases, the manifold may need to be removed and cleaned separately, which can be a time-consuming process.

Alternative Methods for Cleaning Microbore System Of A Heating System

As seen with power flushing microbore systems, some limitations have to be considered when cleaning these systems. Some of the most effective alternatives include:

Chemical cleaner:

An improved solution is to add a chemical cleaner to the heating system, which would discourage the formation of sludge and debris. These cleaners reduce the chemical activities that result in rusting and corrosion within the pipes and radiators. This will contribute to optimizing lower-level cleaning to reduce the extent to which highly invasive cleaning is necessary.

Magnetic Filters:

Fixing a Magnetic filter on the heating system prevents the build-up of sludge or debris that would otherwise accumulate within the pipes. These magnetic filters help to pull metallic particles from the circulation system and prevent them from circulating. This can eliminate opportunities for congestion formation and enhance the overall outcomes of operations.

Mains Flushing:

For power flushing, rather than employing what is usually referred to as the average power flushing machine that works under high flow, a mains flushing pressure can be used. This is less stressful for the pipes, and hence, there is less chance of damaging them.

Manual Cleaning For A Radiator:

In some applications, the only efficient way of cleaning a microbore system is by hand. This impliesrepiping the radiator and the pipeline, if possible; cleaning individual radiators; and cleaning pipework, if visible and accessible. Though this is a time-consuming method of cleaning, it is one of the most efficient methods of washing the system and getting rid of any sludge or debris present.

System Replacement:

Sometimes, the microbore system is very congested or severely worn out; in this case, the whole system may have to be changed. This is probably going to be the costliest solution since the system might just be irreparable.

When is the Power Flush technique Safe for Microbore Pipes?

Thus, even though there are risks in power flushing microbore pipes, it can be done safely, if at all. Before carrying out a power of the system, it is always advisable to evaluate the state of the system first. Here are some factors to consider:

Age of the System:

If the microbore system is newer and in good condition, it may be fine to power flush. Older systems or those that have not been serviced often may have corroded pipes that may be stained by the high force.

Level of Blockage:

If the blockage is only partial, a power flush may also be capable of clearing it out. However, if the problem of sludge accumulation is acute, it is sometimes more rational to apply a more sparing approach that can prevent total blockage.

Professional Assessment:

It is always preferable to get the approval of a professional heating engineer before going for a power flush. They can inspect the pipes and radiators and tell you what to do.

FAQs

Can you power flush a microbore system?

It should be noted that microbore radiator systems can be power flushed,

Can you power flush a 10mm pipe?

Yes, power flushing should be done methodologically, with an eye for control and detail, to avoid ruining pipes or causing blockages.

Is Microbore heating any good?

Microbore heating is effective for modern installations due to its flexibility and ease of concealment, but due to its smaller pipe size, it requires regular maintenance to prevent blockages.

Why is power flush so expensive?

Power flushing is expensive because it requires specialized equipment and skilled labor, and it can take several hours to clean the entire heating system thoroughly.

Conclusion

All in all, although power flushing might prove a useful method in cleaning a central heating system, it is not always practical for microbore pipes. The requirement of these pipes is comparatively small, and as such, they are more susceptible to blockages and harm; the pressure described in the power flushing is simply too much stress for the pipes.

Nonetheless, if the situation is properly evaluated and the right strategy is applied, it may sometimes be possible to safely power flush a microbore system. Other options, including magnetic filters, mains flushing and manual cleaning, are also available. However, if you are still stumped about how to keep your microbore system in good working order, it would be beneficial to speak to fully qualified heating engineers or local plumbers.